Standard MIL-SPEC Packages

starting at $399!

RRO offers custom and standard mil-spec testing packages starting at $399. Price is for typical Mil-Std testing that is 1 business day or less. Standard testing methods available include MIL-PRF-13830B and MIL-F-48616, and more.

Military Specifications Definitions

MIL-C-48497A (STANDARD RROI TEST)

This specification establishes the durability requirements for single layer and multi-layer interference coatings used on optical materials. Optical components cannot show signs of deterioration or abrasion after each of the following tests:

Click here for more

Military Specifications Definitions

MIL-C-48497A (STANDARD RROI TEST)

This specification establishes the durability requirements for single layer and multi-layer interference coatings used on optical materials. Optical components cannot show signs of deterioration or abrasion after each of the following tests:

Required:

- Adhesion: A 1/2″ wide strip of cellophane tape is pressed against the coated surface and quickly removed

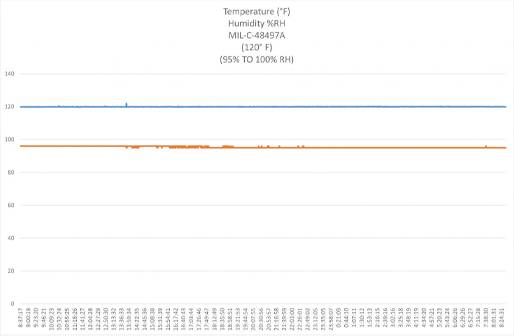

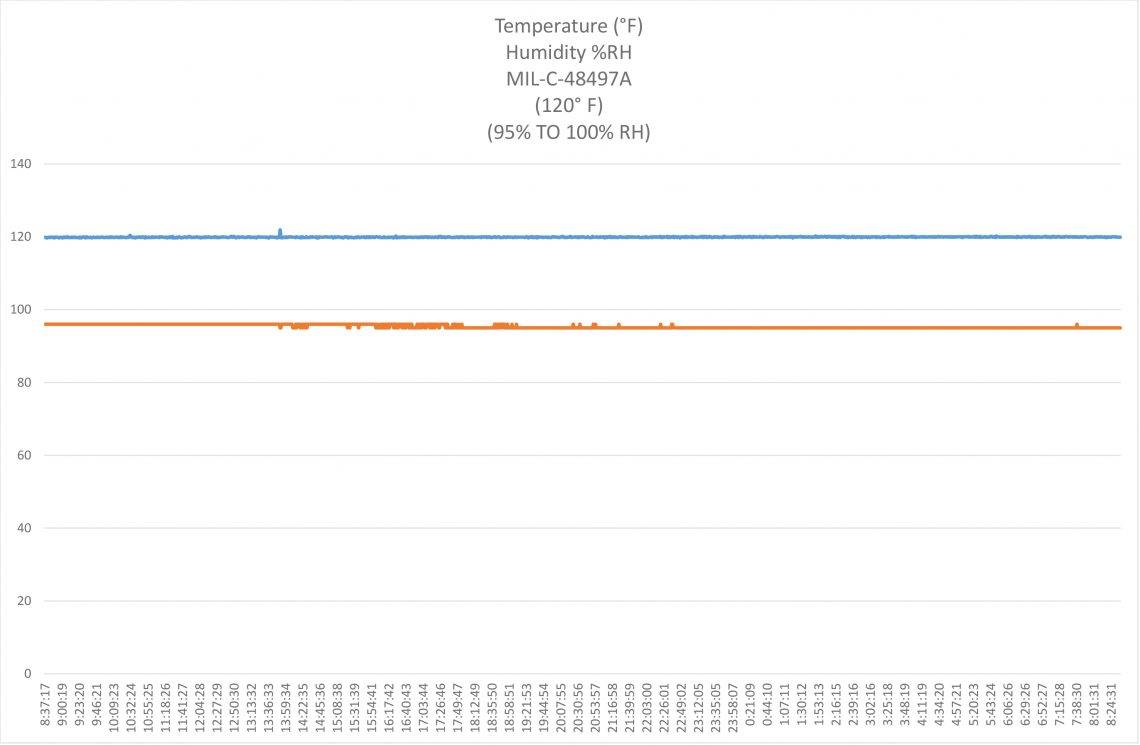

- Humidity: Components are exposed to an atmosphere of 120° ± 4° and 95 to 100% relative humidity

- Moderate Abrasion: Coated optical components are rubbed with a cheese cloth pad for 25 cycles (50 strokes)

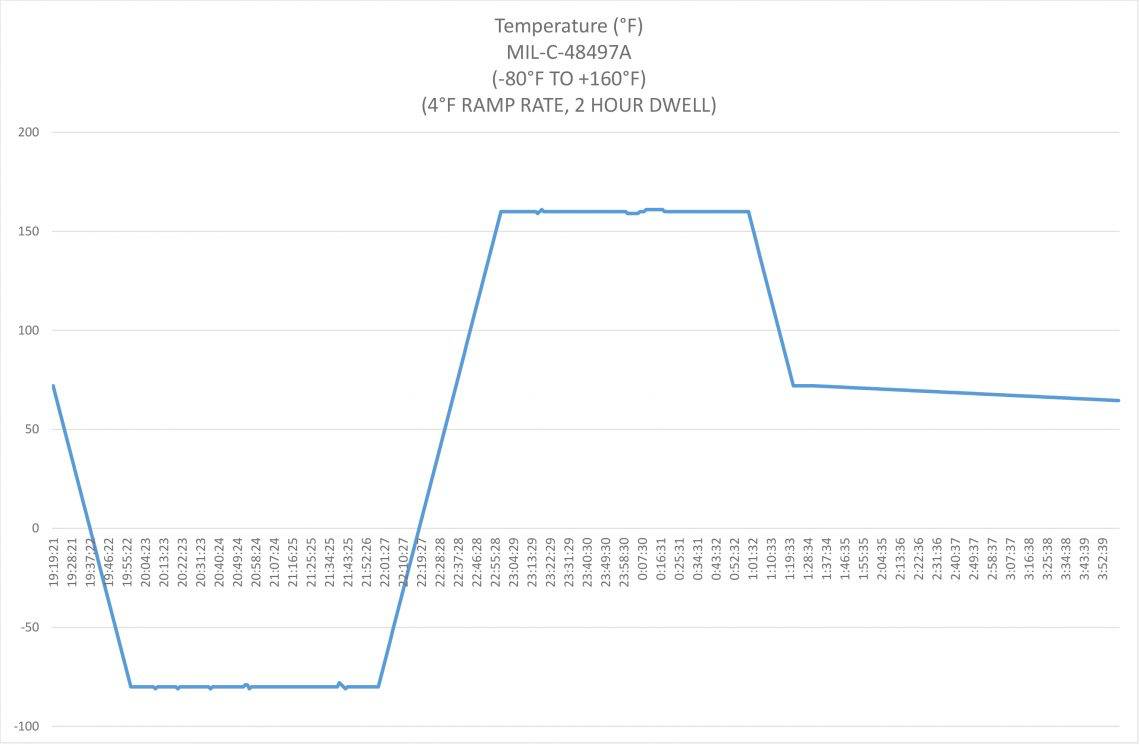

- Temperature: Components are exposed to temperatures of -80° and +160° for 2 hours at each temperature

- Solubility and Cleanability: Coated components are immersed in trichloroethylene, acetone, and ethyl alcohol and wiped with cheesecloth

Optional:

- Severe Abrasion: A MIL-E-12397 compliant eraser is rubbed over the coated surface for 20 complete cycles (40 strokes)

- Salt Solubility: Coated components are immersed in a saline solution for 24 hours

- Water Solubility: Coated components are immersed in distilled water

MIL-C-675C

This specification establishes the durability and abrasion resistance requirements of anti-reflection interference films used on optical materials. Optical components cannot show signs of deterioration or abrasion after each of the following tests:

Required:

- Salt Solubility: Coated optical components are immersed in a saline solution for 24 hours

- Humidity: Components are exposed to an atmosphere of 120° ± 4° and 95 to 100% relative humidity

- Salt Spray Fog: Components are exposed to a salt spray fog for 24 hours

- Severe Abrasion: A MIL-E-12397 compliant eraser is rubbed over the coated surface for 20 complete cycles (40 strokes)

- Moderate Abrasion: Coated optical components are rubbed with a cheese cloth pad for 25 cycles (50 strokes)

- Adhesion: A 1/2″ wide strip of cellophane tape is pressed against the coated surface and quickly removed

MIL-C-675C

This specification establishes the durability requirements for a mirror coating consisting of a deposited aluminum reflective film overlaid with a transparent dielectric protective film. Optical components cannot show signs of deterioration or abrasion after each of the following tests:

Required:

- Temperature: Components are exposed to temperatures of -80° and +160° for 2 hours at each temperature

- Adhesion: A 1/2″ wide strip of cellophane tape is pressed against the coated surface and quickly removed

- Moderate Abrasion: Coated optical components are rubbed with a cheese cloth pad for 25 cycles (50 strokes)

Optional:

- Humidity: Components are exposed to an atmosphere of 120° ± 4° and 95 to 100% relative humidity

- Salt Spray: Components are exposed to a salt spray

Capabilities

Rainbow Research Optics (RRO) is a ITAR compliant and our quality management systems are ISO 9001:2015 certified. This allows us to customize testing procedures while maintaining compliance and accountability.

| Humidity | Temperature between 60°F to 200°F Relative humidity from 5% to 99% |

| Temperature Cycling | Temperature between -75°C (-103°F) to 200°C (392°F) Ramp rate of thermal cycling (up to 10°C/min) |

| Salt Spray Fog | Parts/components are exposed to a salt spray fog for a set period of time Temperature between 60°C (140°F) to 100°C (212°F) |

| Abrasion | Either cheesecloth (CCC-C-440) or eraser (MIL-E-12397) abrasion material Either 1.0lb (moderate abrasion) or 2.0-2.5lb (severe abrasion) of pressure |

| Adhesion | A 1/2″ wide strip of cellophane adhesive is pressed against the coated surface Adhesive can be removed rapidly or gradually |

| Salt Solubility | Sodium chloride density in water Duration of time soaking in salt water |