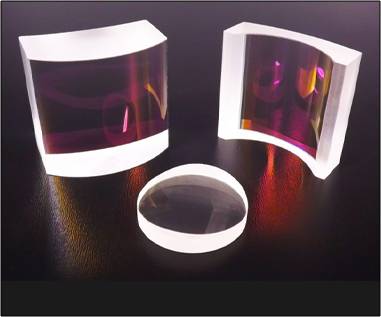

Standard and Custom Lenses

A lens is one of the most basic and important optical elements. Image formation is one of the main uses for a lens. Since lenses are transmissive, light throughput is always a worthwhile consideration.

Generally speaking, selecting a suitable optical material is critical to maximizing light transmitting through a lens element. In addition to our standard products (shown below), we can fabricate and coat lenses to meet our customers exact requirements.

We Also Offer

Grinding/Polishing Tools & Test Plates

Most lenses include spherical surfaces. It requires experience to generate, polish, and test lenses. Each lens radius requires dedicated grinding and polishing tools. In addition, a test plate of a known radius is typically required to verify the spherical surface.

RROI currently has over 1,800 grinding and polishing tools and 1,000 Test Plate sets. Working with existing tooling and test plates saves both time and money for demanding, time-sensitive requirements.

Materials

Stock materials include BK7 and fused silica, in addition to specialty optical materials like calcium fluoride (CaF2), germanium (Ge), magnesium fluoride (MgF2), silicon (Si), zinc selenide (ZnSe), and zinc sulfide (ZnS).

Assemblies and Bonding

We produce singlet and multi-element lenses for laser and imaging applications.

Minimum Quantities

No minimum requirements. We offer single prototypes to production volumes of lenses, primarily for defense, biomedical, education/research, and laser applications.

Mass Production

While we can respond very quickly for small volume and prototype requests, our lens production capacity is greater than 10,000 pieces per month.

RROI is Your

One-Stop Source

for Standard and

Custom Lenses