Laser Mirrors

Reflecting Laser Mirrors

Partially Reflecting Laser Mirrors

Substrate material: UV fused silica, CaF2 or BK7

S1 Surface Figure: λ/10 @ 633nm

S1 Surface Quality: 10-5 laser quality

S2 Surface Quality: Commercial Finish

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Wedge: <3 are min.

Clear Aperture: >85% of diameter

Chamfer: 0.3mm at 45 typical

Damage Thredold: >10j/cm2 10ns

Adhesion Threshold: Per MIL-C-675A

HOW TO ORDER

| Size | ||

|---|---|---|

| Code | DaumeterD | ThicknessT |

| 0512 | 0.500″ | 0.125″ |

| 0525 | 0.500″ | 0.250″ |

| 0537 | 0.500″ | 0.375″ |

| 0712 | 0.750″ | 0.125″ |

| 0725 | 0.750″ | 0.250″ |

| 0737 | 0.750″ | 0.375″ |

| 1012 | 1.000″ | 0.125″ |

| 1025 | 1.000″ | 0.250″ |

| 1037 | 1.000″ | 0.375″ |

| 1525 | 1.500″ | 0.250″ |

| 1537 | 1.500″ | 0.375″ |

| 2025 | 2.000″ | 0.250″ |

| 2037 | 2.000″ | 0.375″ |

| 3037 | 3.000″ | 0.375″ |

| 3050 | 3.000″ | 0.500″ |

| 4050 | 4.000 | 0.500″ |

| Standard Wavelength (nm) | ||

|---|---|---|

| 193 | 694 | |

| 213 | 755 | |

| 244-257 | 780 | |

| 248 | 800 | |

| 266 | 830 | |

| 308 | 850 | |

| 337 | 940 | |

| 355 | 1053 | |

| 364 | 1047,1053 | |

| 488-529 | 1064 | |

| 488-515 | 1235 | |

| 527 | 1319 | |

| 532 | 1550 | |

| 589 | 2010 | |

| 633 | 2100 | |

| 670 | 2940 | |

| Refkectabce (%) | ||

|---|---|---|

| 10±2 | ||

| 20±3 | ||

| 25±3 | ||

| 30±3 | ||

| 35±3 | ||

| 40±3 | ||

| 50±5 | ||

| 60±4 | ||

| 70±4 | ||

| 75±4 | ||

| 80±4 | ||

| 85±4 | ||

| 90±3 | ||

| 95±2 | ||

| 95±1 | ||

| 99±0.5 | ||

* Other percentage of reflection and dimensions available in prototype and production quantities.

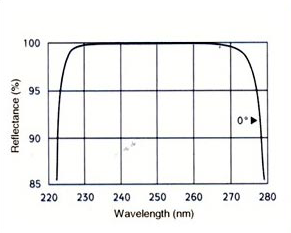

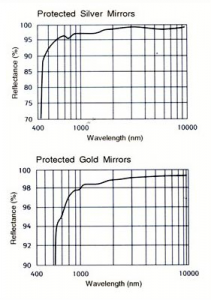

High Energy Laser Mirrors

These mirrors cover the laser lines of ArF (λ = 193 nm) and XeF (λ = 352 nm). These external cavity, high-energy excimer laser mirrors have been designed to withstand high pulsed powers. Each optic provides better than λ/10 surface flatness and surface finishes of 10-5 scratch-dig.

Features:

ArF and XeF Excimer Laser Line Mirrors

High Damage Threshold

High Energy Excimer Laser Cavity Mirrors

Substrate material: UV CaF2 or VUV MgF2

Surface Figure: λ/10 @ 633nm

Surface Quality: 20-10 laser quality

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Wedge: <3 are min.

Reflectance: R > 97% at 633nm and R > 99.5% at 248nm ~ 353nm

Clear Aperture: >85% of diameter

Chamfer: 0.3mm at 45 typical

Damage Thredold: 1j/cm2 10nsec pulse

Adhesion Threshold: Per MIL-C-675APer MIL-C-675A

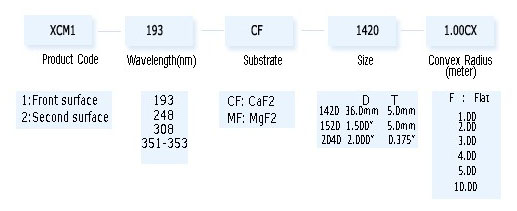

HOW TO ORDER

* Other percentage of reflection and dimensions available in prototype and production quantities.

High Energy Excimer Laser Mirrors

These mirrors cover the laser lines of ArF (λ = 193 nm) and XeF (λ = 352 nm). These external cavity, high-energy excimer laser mirrors have been designed to withstand high pulsed powers. Each optic provides better than λ/10 surface flatness and surface finishes of 10-5 scratch-dig.

Features:

ArF and XeF Excimer Laser Line Mirrors

High Damage Threshold

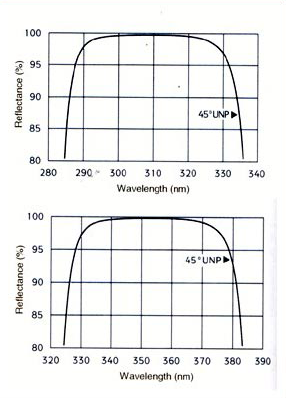

Excimer Laser Mirrors, ArF(193nm) / KrF(248nm)

Substrate material: BK7

S1 Surface Figure: λ/10 @ 633nm

S1 Surface Quality: 10-5 laser quality

S2 Surface Quality: Commercial Finish

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Min. Reflectance: ArF ≥ 97.0% KrF ≥ 99.0%

Clear Aperture: >85% of diameter

Chamfer: 0.3mm at 45 typical

Damage Thredold: 1 j /cm2 10ns pulse

Adhesion Threshold: Per MIL-C-675A

Excimer Laser Mirrors, XeCl(308nm) / XeF(351-353nm)

Substrate material: UV fused Silica or BK7

S1 Surface Figure: λ/10 @ 633nm

S1 Surface Quality: 10-5 laser quality

S2 Surface Quality: Commercial Finish

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Min. Reflectance: ArF ≥ 97.0% XeF ≥ 99.0%

Clear Aperture: >85% of diameter

Chamfer: 0.3mm at 45 typical

Damage Thredold: 1 j /cm2 10ns pulse

Adhesion Threshold: Per MIL-C-675A

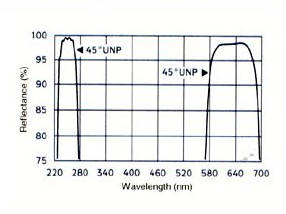

High Energy Excimer / He-Ne Laser Mirrors

Substrate material: UV fused Silica

S1 Surface Figure: λ/10 @ 633nm

S1 Surface Quality: 10-5 laser quality

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Wedge: < 3 arc min.

Clear Aperture: >85% of diameter

Chamfer: 0.3mm at 45 typical

Adhesion Threshold: Per MIL-C-675A

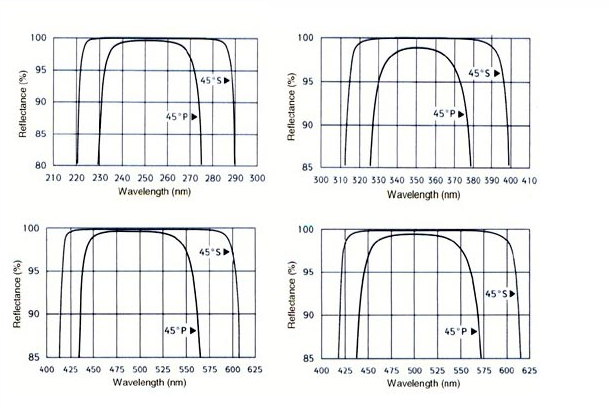

Argon-Ion Laser Mirrors

Ar-Ion laser line mirrors have a specialized coating that provides a high reflectance over wavelength ranges coincident with the emission of an Ar-Ion laser. The coating has a high damage threshold suitable for use with the output beam from large-frame high-powered CW (continuous wave) Ar-Ion lasers.

Argon-Ion Laser Mirrors

Substrate material: UV fused silica, CaF2 or BK7

S1 Surface Figure: λ/10 @ 633nm

S1 Surface Quality: 10-5 laser quality

S2 Surface Quality: Commercial Finish

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Wedge: <3 are min.

Clear Aperture: >85% of diameter

Chamfer: 0.3mm at 45 typical

HOW TO ORDER

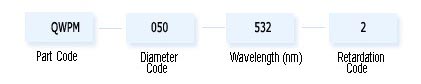

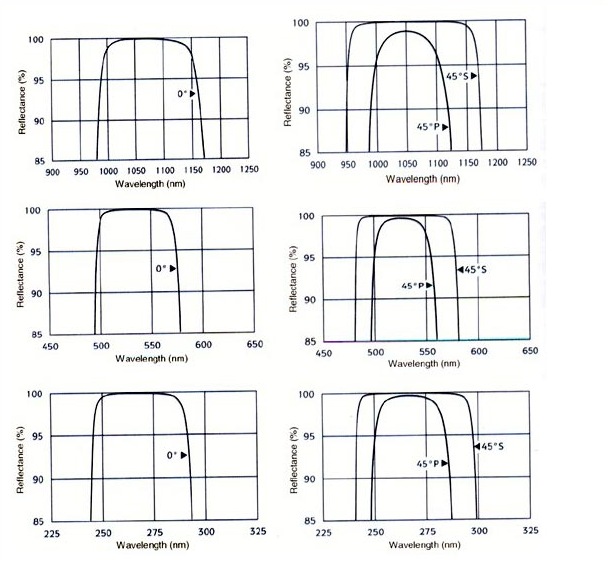

Nd:YAG Laser Mirrors

Nd:YAG Laser Mirrors

Substrate material: BK7

S1 Surface Figure: λ/10 @ 633nm

S1 Surface Quality: 10-5 laser quality

S2 Surface Quality: Commercial Finish

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Wedge: ≤3 are min.

Clear Aperture: >85% of diameter

Chamfer: 0.3mm at 45 typical

Damage Threshold: 10j /cm2 , 10ns pulse

Adhesion and Durability: Per MIL-C-675A

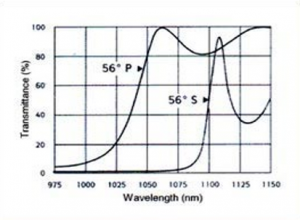

Nd:YLF Laser Mirrors

Nd:YLF Laser Mirrors

Substrate material: BK7

S1 Surface Figure: λ/10 @ 633nm

S1 Surface Quality: 10-5 laser quality

S2 Surface Quality: Commercial Finish

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Wedge: ≤3 are min.

Clear Aperture: >85% of diameter

Chamfer: 0.3mm at 45 typical

Damage Threshold: 10j /cm2 , 10ns pulse

Adhesion and Durability: Per MIL-C-675A

HOW TO ORDER

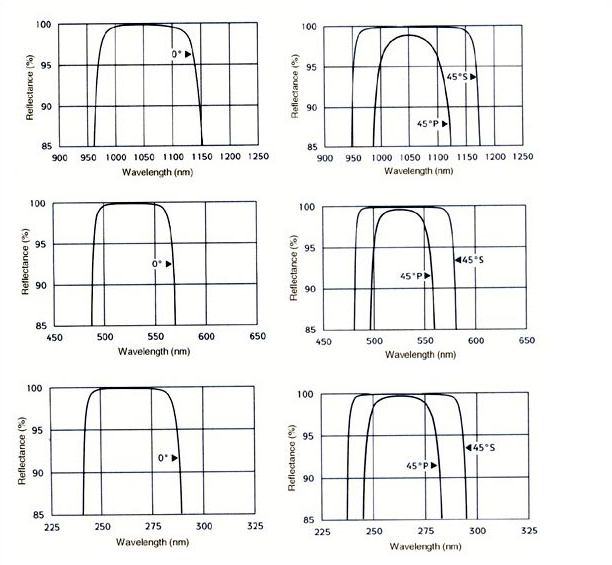

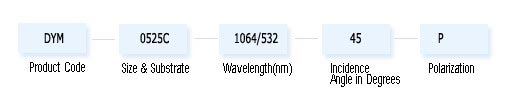

Dual Reflective

Nd:YAG/YLF Laser Mirrors

Substrate material: BK7

S1 Surface Figure: λ/10 @ 633nm

S1 Surface Quality: 10-5 laser quality

S2 Surface Quality: Commercial Finish

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Wedge: ≤3 are min.

Radius Tolerance: ±0.5 %

Clear Aperture: >85% of diameter

Chamfer: 0.3mm at 45 typical

Damage Threshold: 10j /cm2 , 10ns pulse

Adhesion and Durability: Per MIL-C-675A

HOW TO ORDER

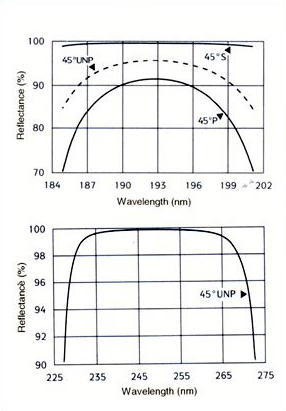

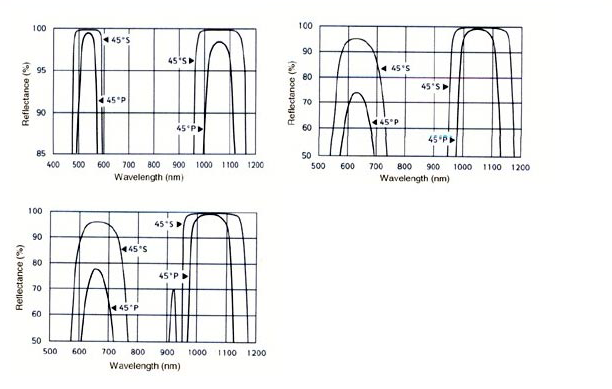

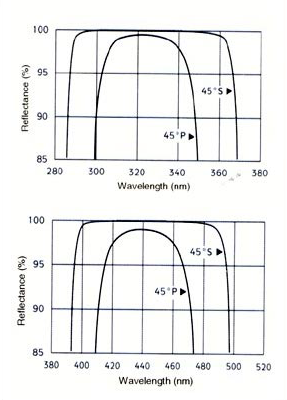

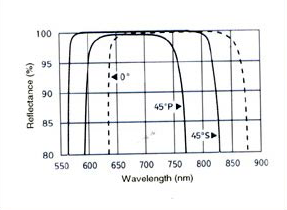

0-45 degrees Laser Mirrors

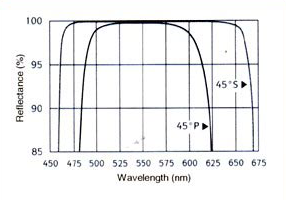

0-45° Visible Laser Mirrors (488-694 nm)

Substrate: UV fused Silica or BK7

Surface Figure: λ/10 @ 633 nm

S1 Surface Quality: 10-5

S2 Surface Quality: Commercial Polish

Diameter Tolerance: + 0.0/0.20 mm

Thickness Tolerance: ± 0.25 mm

Clear Aperture: > 85% of diamete

Chamfer: 0.3 mm at 45° typical

Adhesion and Durability: Per MIL-C-675A

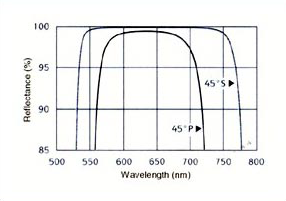

0-45° Diode Laser Mirrors

Substrate: BK7

Surface Figure: λ/10 @ 633 nm

S1 Surface Quality: 10-5

S2 Surface Quality: Commercial Polish

Diameter Tolerance: + 0.0/0.20 mm

Thickness Tolerance: ± 0.25 mm

Clear Aperture: > 85% of diamete

Chamfer: 0.3 mm at 45° typical

Adhesion and Durability: Per MIL-C-675A

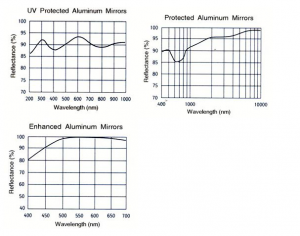

Aluminum, Silver and Gold Laser Mirrors

Aluminum Mirrors

Substrate material: UV fused silica orBK7

S1 Surface Figure: λ/10 @ 633nm

S1 Surface Quality: 10-5 laser quality

S2 Surface Quality: Commercial Finish

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Wedge: ≤3 are min.

Clear Aperture: >85% of diameter

Chamfer: 0.3mm at 45 typical

Adhesion and Durability: Per MIL-C-675A

Protected Silver and Gold Mirrors

Substrate material: BK7

S1 Surface Figure: λ/10 @ 633nm

S1 Surface Quality: 10-5 laser quality

S2 Surface Quality: Commercial Finish

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Wedge: ≤3 are min.

Clear Aperture: >85% of diameter

Chamfer: 0.3mm at 45 typical

Adhesion and Durability: Per MIL-C-675A

Miscellaneous Laser Mirrors

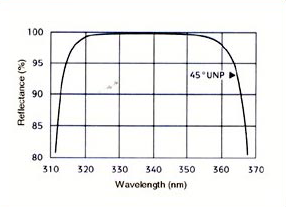

Nitrogen Laser Mirrors

Substrate material: UV fused silica or BK7

S1 Surface Figure: λ/10 @ 633nm

S1 Surface Quality: 10-5 laser quality

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Wedge: <3 are min.

Clear Aperture: >85% of diameter

Chamfer: 0.3mm at 45 typical

Damage Thredold: 1j/cm2 10nsec Pulse

Adhesion Threshold: Per MIL-C-675A

HOW TO ORDER

He-Cd Laser Mirrors

Substrate material: UV fused silica or BK7

S1 Surface Figure: λ/10 @ 633nm

S1 Surface Quality: 10-5 laser quality

S2 Surface Quality: Commercial Polish

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Clear Aperture: >85% of diameter

Chamfer: 0.3mm at 45 typical

Damage Thredold: 1j/cm2 10nsec Pulse

Adhesion Threshold: Per MIL-C-675A

Copper Vapoor Laser Mirrors

Substrate material: UV fused silica, CaF2 or BK7

S1 Surface Figure: λ/10 @ 633nm

S1 Surface Quality: 15-5 laser quality

S2 Surface Quality: Commercial Polish

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Clear Aperture: >85% of diameter

Chamfer: 0.3mm at 45 typical

Damage Thredold: 1 j/cm2 10nsec pulse

Adhesion Threshold: Per MIL-C-675A

HOW TO ORDER

He-Ne Laser Mirrors (632.8nm)

Substrate material: UV fused silica, BK7

S1 Surface Figure: λ/10 @ 633nm

S1 Surface Quality: 15-5 laser quality

S2 Surface Quality: Commercial Polish

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Clear Aperture: >85% of diameter

Chamfer: 0.3mm at 45 typical

Damage Thredold: > 1 j/cm2 10nsec pulse

Adhesion Threshold: Per MIL-C-675A

HOW TO ORDER

Ruby Laser Mirrors (694.3nm)

Substrate material: UV fused silica, BK7

S1 Surface Figure: λ/10 @ 633nm

S1 Surface Quality: 15-5 laser quality

S2 Surface Quality: Commercial Polish

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Clear Aperture: >85% of diameter

Chamfer: 0.3mm at 45 typical

Damage Thredold: > 10 j/cm2 10nsec pulse

Adhesion Threshold: Per MIL-C-675A

HOW TO ORDER

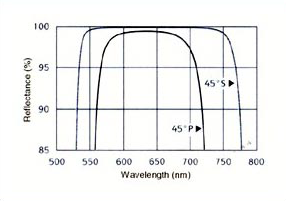

Alexandrite Laser Mirrors (720-780nm)

Substrate material: UV fused silica, BK7

S1 Surface Figure: λ/10 @ 633nm

S1 Surface Quality: 10-5 laser quality

S2 Surface Quality: Commercial Polish

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Clear Aperture: >85% of diameter

Chamfer: 0.3mm at 45 typical

Damage Thredold: > 10 j/cm2 10nsec pulse

Adhesion Threshold: Per MIL-C-675A

HOW TO ORDER

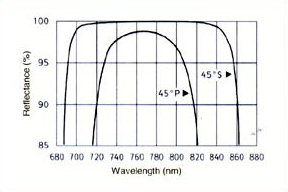

Diode Laser Mirrors

Substrate material: BK7

S1 Surface Figure: λ/10 @ 633nm

S1 Surface Quality: 10-5 laser quality

S2 Surface Quality: Commercial Polish

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Clear Aperture: >85% of diameter

Chamfer: 0.3mm at 45 typical

Minimum Reflectance: ≥99%

Adhesion Threshold: Per MIL-C-675A

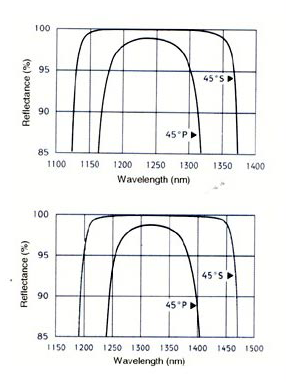

Forsterite (1235nm), Iodine (1315nm) Laser Mirrors

Substrate material: UV fused silica or BK7

S1 Surface Figure: λ/10 @ 633nm

S1 Surface Quality: 10-5 laser quality

S2 Surface Quality: Commercial Polish

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Clear Aperture: >85% of diameter

Chamfer: 0.3mm at 45 typical

Damage Thredold: 1 j/cm2 10ns pulse

Adhesion Threshold: Per MIL-C-675A

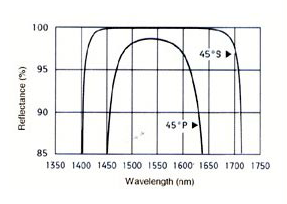

Er:Glass Laser Mirrors

Substrate material: BK7

S1 Surface Figure: λ/10 @ 633nm

S1 Surface Quality: 10-5 laser quality

S2 Surface Quality: Commercial Polish

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Clear Aperture: >85% of diameter

Chamfer: 0.3mm at 45 typical

Damage Thredold: 5 j/cm2 10ns pulse

Adhesion Threshold: Per MIL-C-675A

HOW TO ORDER

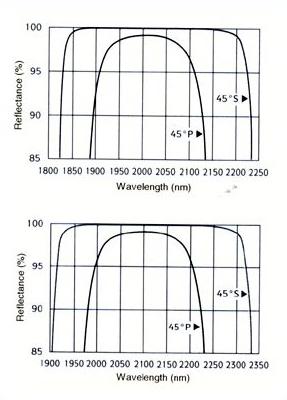

Tm:YAG (2010nm) , Ho:YAG (2100nm) Laser Mirrors

Substrate material: BK7

S1 Surface Figure: λ/10 @ 633nm

S1 Surface Quality: 10-5 laser quality

S2 Surface Quality: Commercial Polish

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Clear Aperture: >85% of diameter

Chamfer: 0.3mm at 45 typical

Damage Thredold: 10 j/cm2 10ns pulse

Adhesion Threshold: Per MIL-C-675A

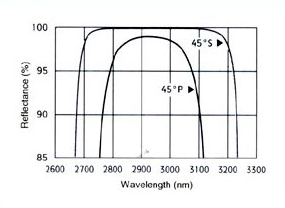

Er:YAG Laser Mirrors (2940nm)

Substrate material: BK7

S1 Surface Figure: λ/10 @ 633nm

S1 Surface Quality: 10-5 laser quality

S2 Surface Quality: Commercial Polish

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Clear Aperture: >85% of diameter

Chamfer: 0.3mm at 45 typical

Damage Thredold: >10 j/cm2 10ns

Adhesion Threshold: Per MIL-C-675A

HOW TO ORDER